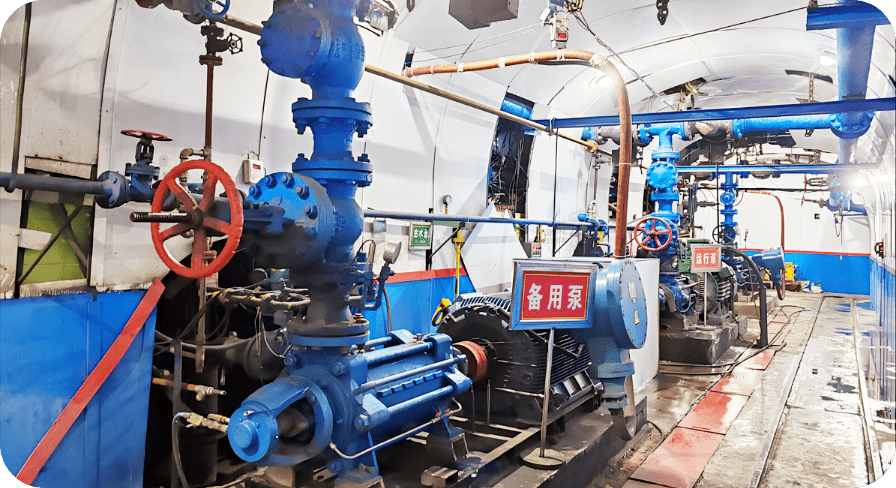

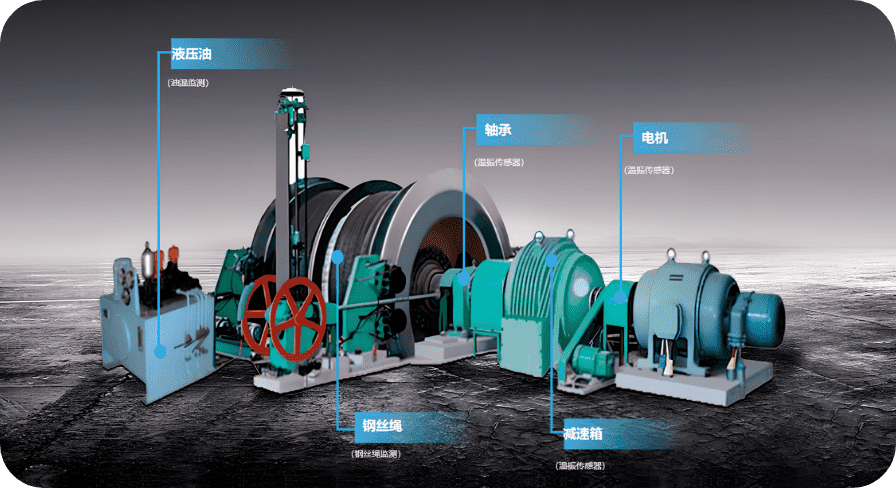

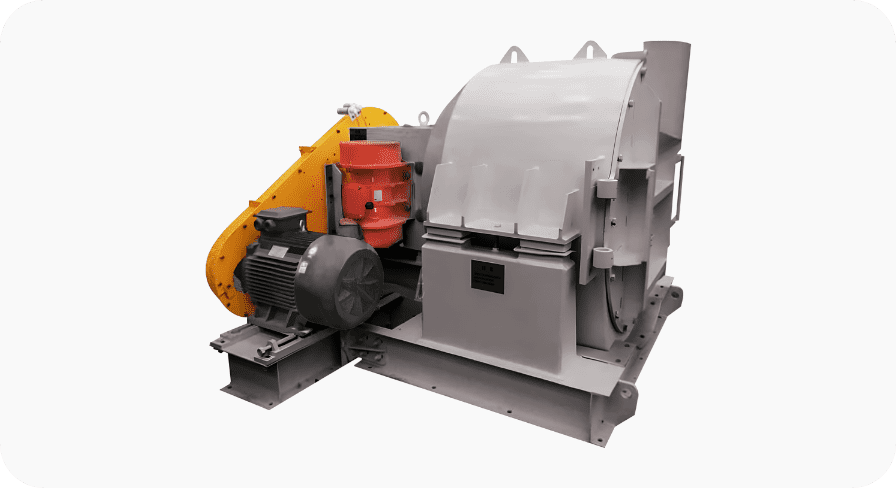

Intelligent Operation and Maintenance of Underground Mining Equipment

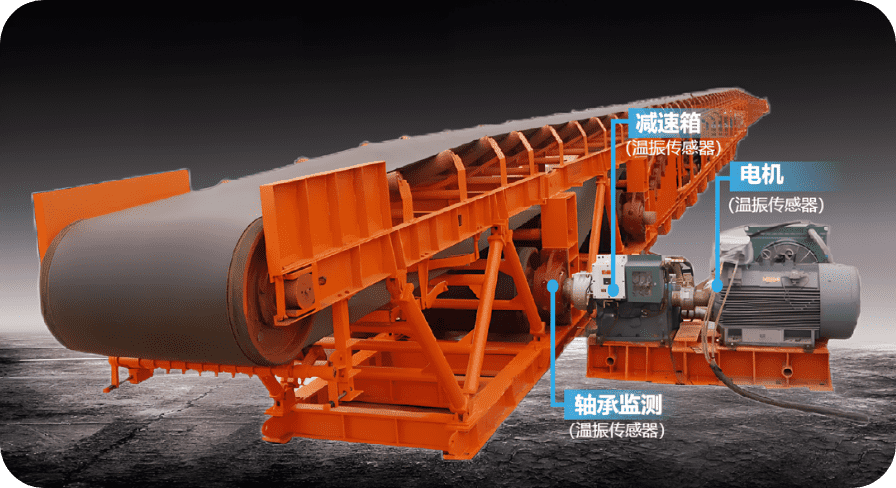

Installation of vibration-temperature integrated sensors and visual AI to monitor motors, gearboxes, bearing seats, and wire ropes of important equipment such as belt conveyors, scraper conveyors, hoists, central water pumps, crushers, etc, realizing real-time online monitoring, analysis and alarm of the operating status of equipment mechanisms through the collection and analysis of data on vibration, temperature, rotational speed and so on. Combined with the operating hours, bearing status, working status, wire rope status and other working condition parameters in the equipment PLC, it can make statistics and assessments on the operation, efficiency and remaining life of the equipment, give operation and maintenance suggestions, realize the management of the whole life cycle of the equipment, and ensure the safety of the whole equipment.

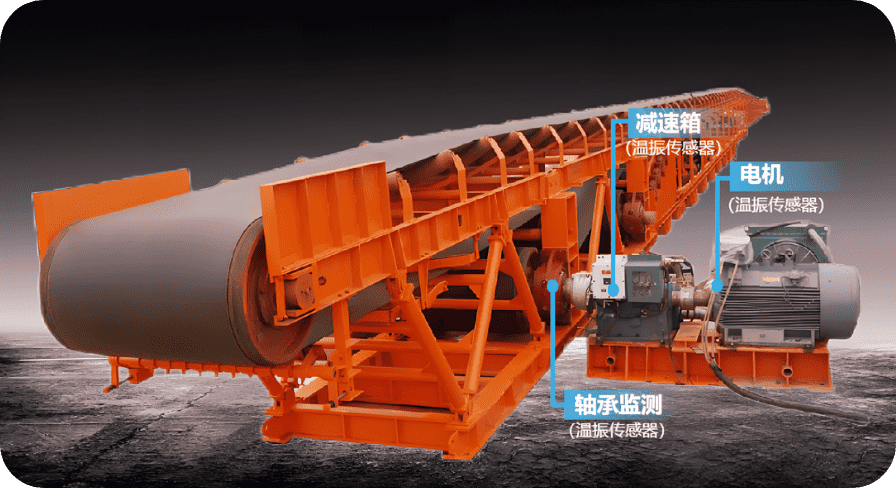

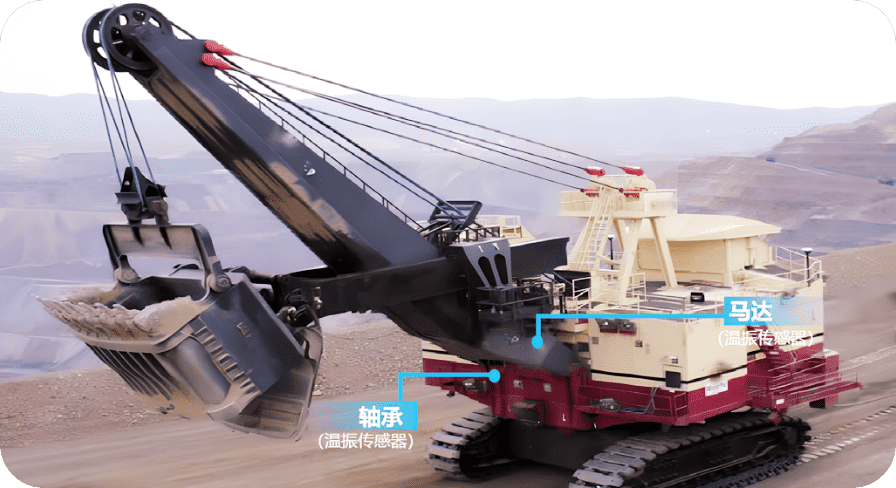

Intelligent Operation and Maintenance of Open-pit Mining Equipment

Installation of vibration-temperature integrated sensors to monitor motors, gearboxes, bearing seats of important equipment such as bucket wheel excavators, belt conveyors, chain bucket shovels, etc, realizing real-time online monitoring, analysis and alarm of the operating status of equipment mechanisms through the collection and analysis of data on vibration, temperature, rotational speed and so on. Combined with the operating hours, bearing status, working status, wire rope status and other working condition parameters in the equipment PLC, it can make statistics and assessment on the operation, efficiency and remaining life of the equipment, give operation and maintenance suggestions, realize the management of the whole life cycle of the equipment, and ensure the safety of the whole equipment.

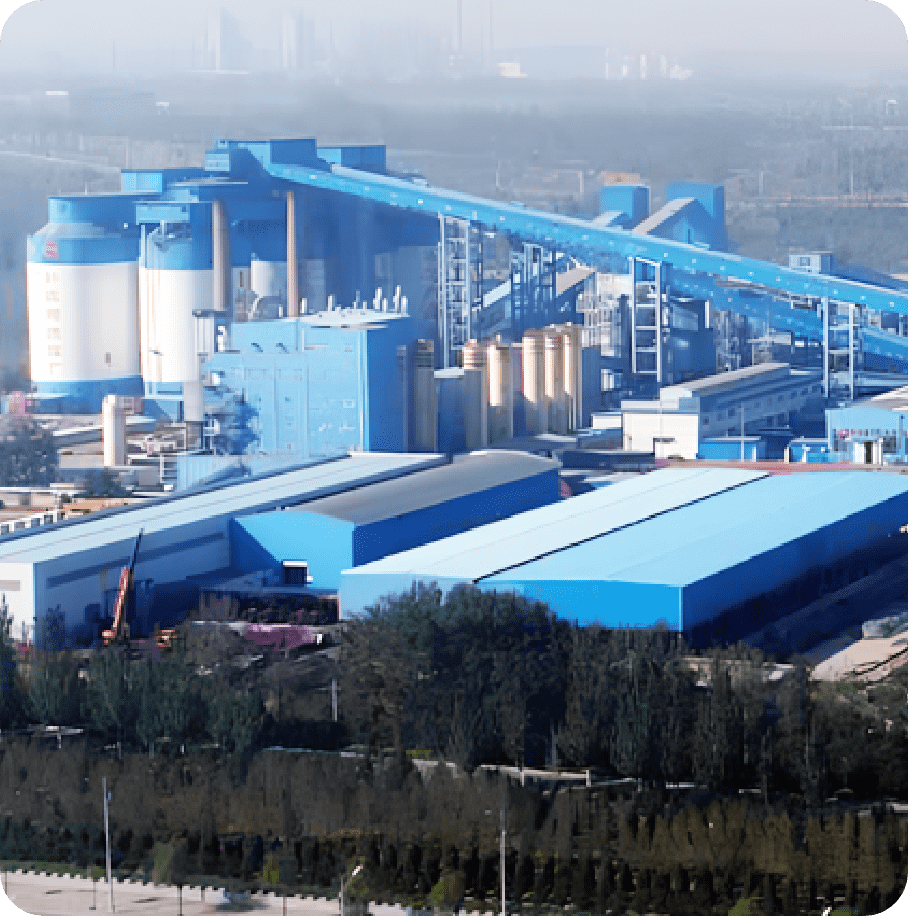

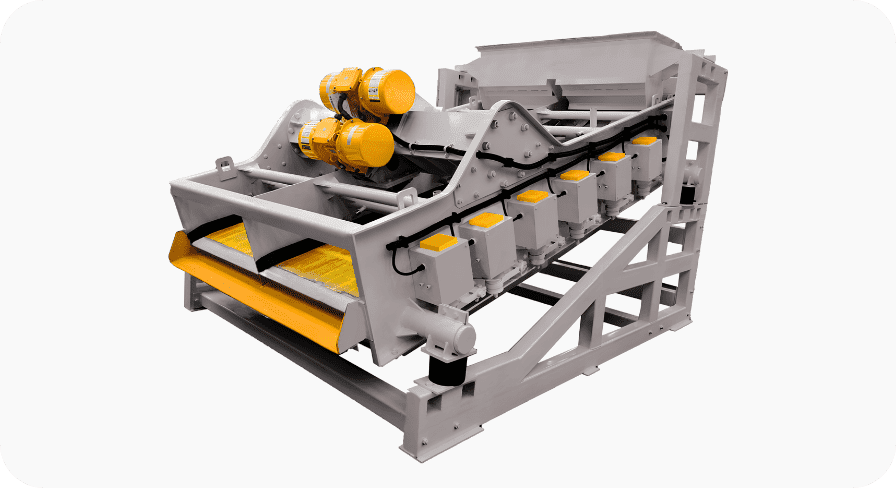

Intelligent Operation and Maintenance of Coal Preparation Plant Equipment

Installation of vibration-temperature integrated sensors and visual AI to monitor motors, gearboxes, and bearing of important equipment such as belt conveyors, coal feeders, vibrating screens, magnetic separator, desliming screen,?demediumizing screen, flotation machine, centrifuge, classifying screen, hoists, crushers, etc, realizing real-time online monitoring, analysis and alarm of the operating status of equipment mechanisms through the collection and analysis of data on vibration, temperature, rotational speed and so on. Combined with the operating hours, bearing status, working status, wire rope status and other working condition parameters in the equipment PLC, it can make statistics and assessments on the operation, efficiency and remaining life of the equipment, give operation and maintenance suggestions, realize the management of the whole life cycle of the equipment, and ensure the safety of the whole equipment.

Back top

Back top

Hotline:

Hotline: